Description

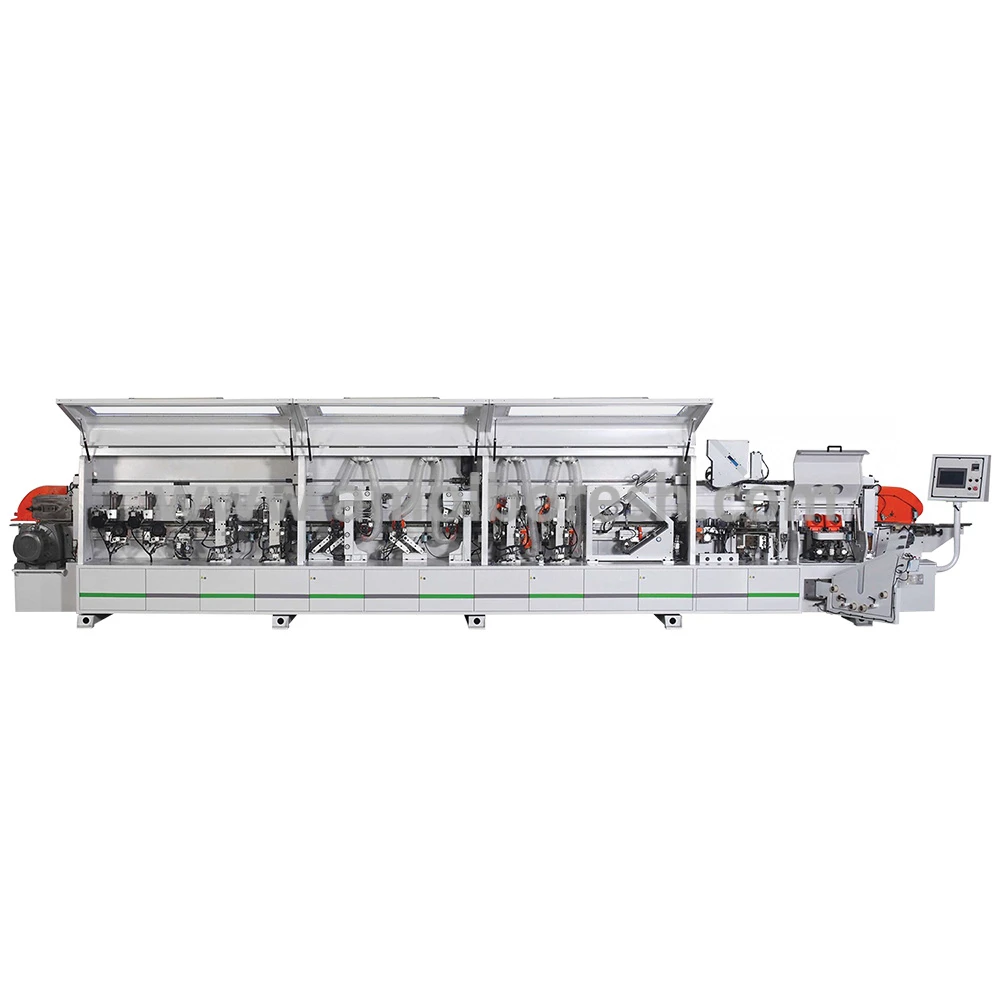

The mz335s edge banding machine is similar to mz330 except that mz335s could adjust width between 1 to 2 MM by PLC controller

The pre-heating system upgrades the workpiece temperature to a certain level, which makes it easier and therefore better to adhere PVC strips to the workpiece. The upside-down saw can cut the extra strips attached to the piece by giving the specified value to the device program. This app can be controlled from the touch screen made by Taiwan Tech. At the end of the machine, the polishing part is a piece of work that removes the bursts and bumps on the piece from the previous operation and cleans it. It should be noted that all electronic components of the device are from the Siemens company from Germany.

The technical specifications of the machine are in the table and put together in order to choose the most suitable for you. From the specifications of the device can be noted the speed of 12/16/21m per minute. If reading these specifications is not enough to fully understand how the device operates, there is a video of how the device works. Since these devices are expensive, we recommend that you pay attention to the table and also watch the video of the product. Learn about the suitability of your device to meet your needs and practices.